Fire assay crucibles are used in smelting of the samples. Crushed rocks, ores are mixed with fire assay flux, then heated and melted in a crucible. Gold, silver and precious metals are captured in a molten state with lead to form a lead alloy (generally called lead button, also known as precious lead), which sinks to the bottom of the crucible due to the specific gravity of the lead alloy. At the same time, the oxides and gangue of the base metals in the sample are combined with fluxes such as silica, borax, sodium carbonate, etc., to form slags such as silicate or borate, which float on them because of their small specific gravity, thereby separating the gold and silver from the sample.

Fire Assaying is done by assay laboratories, a few leading brands are SGS, ALS, Intertek etc. who are capable of testing the purity of precious metals, say, gold, silver, and the platinum group metals. Fire assay crucibles and the fire assaying process are also used by leading mining companies and refiners who need to analysis material ingredients by themselves.

We supply high quality , multi-use Fire Assay Crucibles—– Sizes available include 30, 40, 50, 55 and 65g and we can produce the special size according to customer’s requirement. All crucibles can be packed in crate or cartons with pallet.

Product Instruction

Our universal fire assay crucibles material of construction is fireclay mixed with other refractory materials. They withstand temperatures up to 1300`C. This composition and their design give them an excellent resistance against flux attack, erosion, cracking and thermal shock.

Product Feature

Our crucibles have a longer lifer under harsh working conditions.

They have a high resistance to thermal shock, produce a faster fusion, constant melting speed .

Another important feature is that they are very stable based on their wide bottom which is particularly relevant for furnaces that have an irregular ground due to flux attack and erosion.

Our crucibles design allows nesting, and obtain an optimal space utilization in the warehouse, and minimal transport costs to any location.

Last but not least, their dense body also minimizes absorption losses.

Details of Chemical Content

| Product: | Fire Assay Crucible |

| Production Method: | Roller Forming |

| Typical Chemical Analysis | |

| SiO2 | 54.06% |

| Al2O3 | 37.80% |

| CaO | 0.47% |

| Fe2O3 | 1.54% |

| TiO2 | 1.35% |

| K2O | 0.72% |

| MgO | 0.00% |

| Na2O | 0.00% |

| Working Temperature | 1000℃-1150℃ |

| Firing Temperature | 1400℃ |

| Usage time | 3-5 |

| Specific Gravity | 2.3 |

| Porosity | 25%-26% |

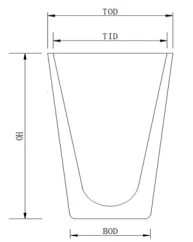

Data of Dimensions

| SCHEMATIC |

|

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NO. | GEM30 | GEM40 | GEM45 | SGSNA 45 | GEM50 | SGSNA50 | GEM65 | GEM75 | GEM75H | 210 | TN4 | |||

| VOLUME(ml) | 200 | 305 | 440 | 440 | 440 | 440 | 570 | |||||||

| OH(mm) | 105±2 | 135±2 | 160±2 | 155±2 | 150±2 | 145±2 | 165±2 | 180±2 | 210±2 | 210±2 | 148±1 | |||

| TOD(mm) | 82±2 | 88±2 | 90±2 | 88±2 | 105±2 | 105±2 | 105±2 | 120±2 | 125±2 | 125±2 | 114+1 | |||

| TID(mm) | 74±1 | 78±1 | 79±1 | 80±1 | 90±1 | 90±1 | 92±1 | 106±2 | 105±2 | 102±2 | 94±1 | |||

| RIM TH | 5±0.5 | 6+0.6 | 6.5±0.6 | 5±0.5 | 8.5+0.8 | 7.5±0.7 | 7.5±0.7 | 7.5±0.7 | 7.5±0.7 | 7.5±0.7 | 10±0.7 | |||

| BOD(mm) | 54±1 | 55+1 | 58±1 | 57±1 | 56±1 | 57±1 | 55±1 | 70±1 | 61±2 | 61±2 | 77±1 | |||

| QTY/20’FCL | 48620 | 36960 | 30000 | 32800 | 30000 | 30600 | 27000 | 17280 | 21600 | |||||

| NEW QTY/20’FCL | 60840 | 43200 | 34320 | 34320 | 30600 | 30600 | 28800 | |||||||

|

Standard package is crate or carton. We manufacture Fire Assay Crucibles of various standard sizes and it can be customized as per demands of the client’s specification and requirement. |

||||||||||||||

Applications

1. Precious metal analysis

2. Mineral assaying

3. Mining laboratory

4. Laboratory Testing

5. Fire Assaying

6. Gold Assaying

Package

wooden cases, cartons with pallet